By: Ashley December 04, 2019 Last Updated :December 05, 2019

Grinding media, used to extract the concentrate for the production of metals, are the main components in the ball mill grinding process. There are different types of milling media used in grinding such as steel balls, ceramic balls and cylpebs.

Steel grinding media are ideal for extracting precious metals in ore beneficiation. Spherical ball mill media have an advantage of better crushing effect when impacting large particles because point contact between balls and raw materials makes the materials easy to be smashed.

| Types | Characteristics |

| Steel | High impact toughness |

| Spherical | Better crushing effect |

steel balls

As the name implies, this grinding media are made of ceramic which is energy-saving and environmentally friendly. The ceramic ball has a Mohs hardness of 9.0, which is second only to diamond, far exceeding the wear resistance of steel and stainless steel. It has the best behavior of wear and its consumption is generally 50% of the steel ball. Under the same conditions, it can extend the service life of the equipment more than 10 times by using ceramic balls.

| Types | Characteristics |

| Wear resistance | 266 times that of high manganese steel 171.5 times that of high chromium cast iron |

| Self-consumption | 50% of the steel ball |

| Noise | Reduction above 15db |

| The current of ball mill | Decrease by more than 20% |

ceramic balls

When the cylpeb is used as the media for grinding, the products of each grain level are relatively uniform. It has certain selectivity for grinding intermediate products and has certain protective effect for minerals, but the crushing strength is not as good as balls. Cylindrical ball mill media is more suitable for fine material grinding because the contact area is larger with the line contacting each other.

cylpebs

Let’s discuss following aspets of charging, size, wear rate and ball to powder ratio in real production.

The charging of the ball mill milling media has a direct impact on grinding efficiency:

(1) If it is too much, the grinding media will be overlapped with each other, thus the crushing capacity of each steel ball cannot be fully utilized and the kinetic energy consumption will be increased.

(2) If it is too little, although the crushing capacity of each steel ball is fully exerted, the total crushing capacity is still limited. Therefore, it is necessary to choose the appropriate amount of ball.

When the speed of the ball mill is fixed and the ball loading is 30% of the total capacity of the cylinder, the ball’s movement is mainly sliding, but it has begun to pour. When the ball load exceeds 40%, the ball is pouring; When it reaches 50%, the surface of the ball is just on the diameter line of the cylinder, so it is easy to pour which is exactly needed for ball mill production.

According to the actual results, when the charging is 40%, the output is the highest. While it is usually about 35% in real production, that is, the volume of the ball is kept lower than the horizontal centerline.

charging of gring media

The ball size in a mill has a significant influence on the mill throughput and power consumption. Here the ball size refers to two aspects, one is the maximum ball size, and the other is the correct ball size ratio.

· The size of the grinding media directly affects the grinding efficiency and product fineness. The larger the diameter, the larger the product particle size and the higher the yield. This empirical formula is currently widely used in European and American countries and regions:

Db——milling balls diameter, in

F——80% sieved feed size, gm

Ss——ore density, t/m3

Wi——work index of ore to be ground, kw·h/t

D——inner diameter of ball mill, ft

Cs——speed of ball mill, %

Km——empirical correction factor (see table below)

| Types of ball mill | Value of Km |

| Wet overflow ball mill | 350 |

| Wet grate ball mill | 330 |

| Dry grate ball mill | 335 |

However, this problem is difficult to solve because there are too many parameters that affect the size of the grinding ball. At the current cognitive level of human, it is impossible to deduce the theoretical calculation formula of the milling ball diameter. This is because it is impossible to include more than a dozen factors that affect the ball diameter, let alone some influencing factors cannot be described by quantity.

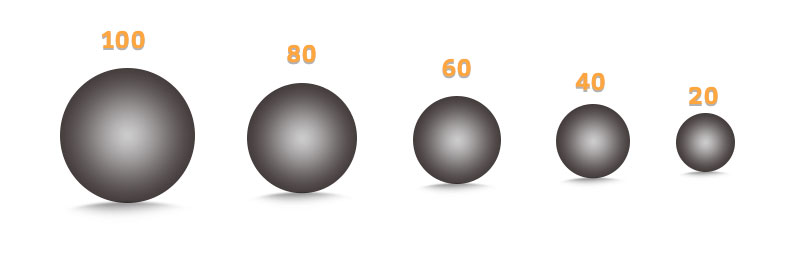

· After determining the proper amount of grinding balls, it is also needed to choose the right ball ratio. The most common in production are the two-stage ratio and the multi-stage ratio. Generally, the multi-stage ratio follows the principle of “less at both ends, more in the middle” which means that large and small balls are less and middle balls are more.

When the ball mill grinds the powder, the following ratio of steel grinding balls have the highest grinding efficiency and belongs to the economic operation state:

| Steel ball diameter (mm) |

Φ 100 | Φ 80 | Φ 60 | Φ 40 | Φ 20 |

| Loading amount | 7.5% | 6.9% | 33.5% | 30.1% | 22% |

different sizes of grinding media

The so-called two-stage ratio is to use two different sizes of steel grinding balls with a large difference in diameter to carry out the grading. The multi-stage is suitable for the materials with small particle size and good abrasive property, while the two-stage ratio is suitable for the materials with large particle size and poor abrasive property.

Steel consumption constitutes a significant proportion of grinding costs in industrial ball mills. Approximately 0.23 billion kg of steel (1986) in the US and over 0.45 billion kg in the world were consumed each year in wet grinding alone. This steel consumption is mainly attributed to the wear of grinding media and liners.

It is known that the total media wear in the grinding process results from three recognized wear mechanisms: abrasion, impact and corrosion.

During this impact process, the rate of ball wear is proportional to the ball mass;

Attrition plays a large part in all fine grinding and has been known and acknowledged. The rate of ball wear during the abrasive process is proportional to the surface area of the ball or the square of the ball diameter.

Electrochemical interactions between the grinding media and minerals, occur especially in wet grinding; resulting in media corrosion. In the same ball mill, the corrosion rate on the surface of each medium will be the same regardless of the size of the mill. Increasing mill size will increase energy consumption, which in turn increases metal loss due to abrasive and impact wear.

wear of grinding media

The ball to powder ratio is determined by the “golden ratio”, that is, the ball: material: (water + air) =1.618:1:0.618. The range of ball-to-water ratio mentioned in textbooks is (1.4 ~ 2.2): 1: (0.45 ~ 0.58), without mention of air and the “golden section”. But in fact, if there is not enough air to scour the water and raw materials, there is no ball grinding efficiency. It’s a kind of optimal allocation principle, but the specific will be determined according to the material, the grinding media and the ball mill.

In order to make full use of the effective volume of the ball mill, materials, water and grinding media should occupy about 80% of the effective volume of the ball mill.

Latest blog

By:AshleyMarch 20, 2020

By:AshleyMarch 20, 2020

By:AshleyMarch 14, 2020

By:AshleyMarch 14, 2020

By:AshleyDecember 28, 2019

By:AshleyDecember 28, 2019

By:AshleyDecember 20, 2019

By:AshleyDecember 20, 2019

Contact

E-mail:vip@sinoftm.com

Address: No.168 Wutong Street, High-Tech Industrial Development Zone of Zhengzhou City, China.

Hot Products

Future Prospect

We would like to cooperate with customers all around the world, and welcome you sincerely !

Inquiry Online 7×24 Online